This is how we clean

Pyrolysis for Plastic removal respectively Polymer removal

According to the plastic and the component to be cleaned SCHWING uses a range of machines and processes for Thermal Cleaning. Thus SCHWING can guarantee optimum plastic / polymer removal at economical prices. Here you can find a video animation of the applications and systems for Thermal Cleaning of SCHWING.

The removal of plastic deposits on tools and long components is usually done with VACUCLEAN in an electrically heated vacuum-cleaning chamber. The temperature is measured directly on the component, which is then slowly and carefully heated, whereby a large part of the attached polymers melt and runoff. At approx. 450 °C the remaining polymers disintegrate, the remaining carbon is then removed by supplied air (oxidation).

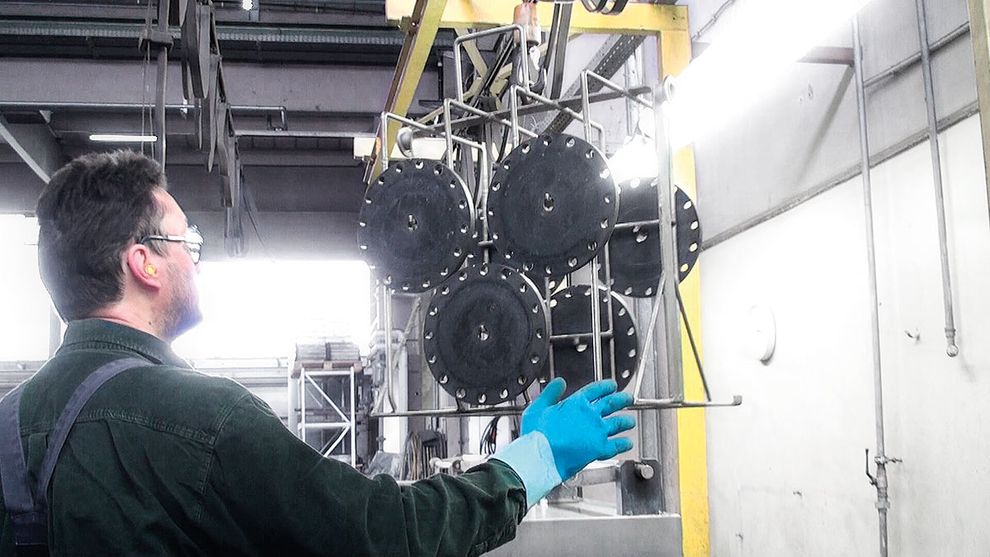

All polymers - even halogenated materials such as PVC or PTFE - including small and medium sized tools and components can be quickly and safely removed with the INNOVACLEAN fluidized bed pyrolysis system. INNOVACLEAN completely carbonizes each polymer without leaving residues, e.g. from injection molding nozzles, die plates or spinnerets and assembled spin packs, static mixers, assembled pumps, non-return valves, hot runner systems and many other components.

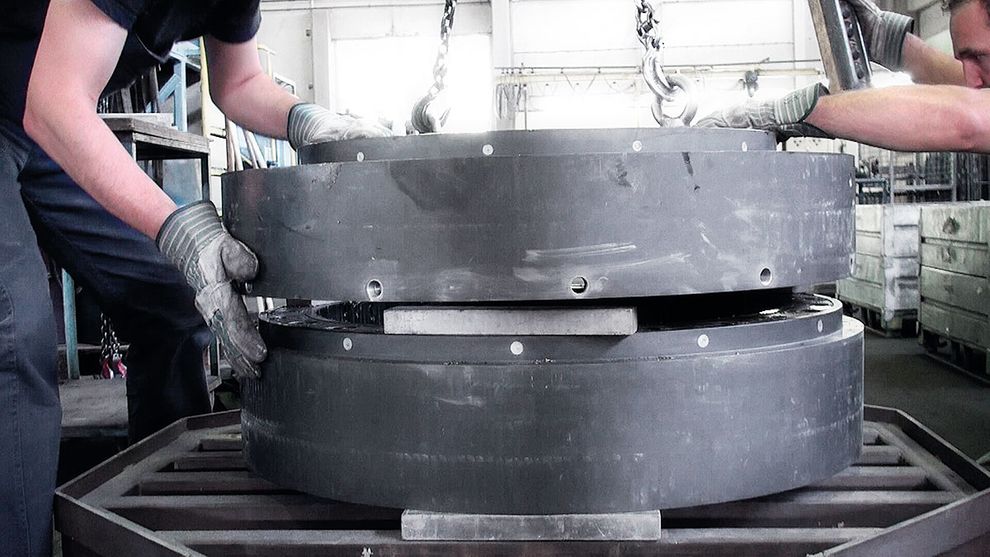

Plastics without halogenated additives are removed with the environmentally friendly MAXICLEAN pyrolysis furnace. The tools and other components to be cleaned are thus not affected mechanically or thermally. MAXICLEAN is especially suitable for particularly large tools and complex components.

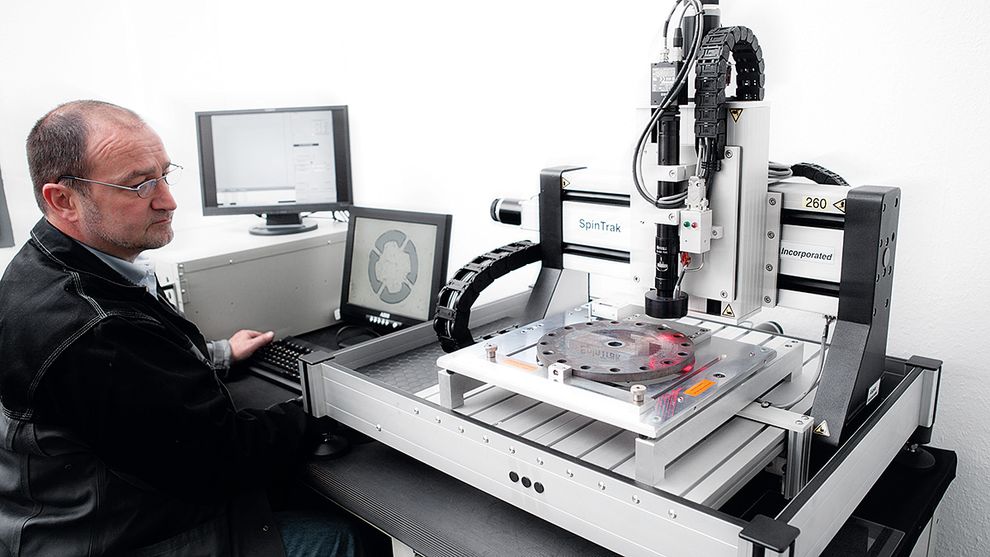

SCHWING also provides customized test and documentation procedures tools and machine parts that are relevant to quality.