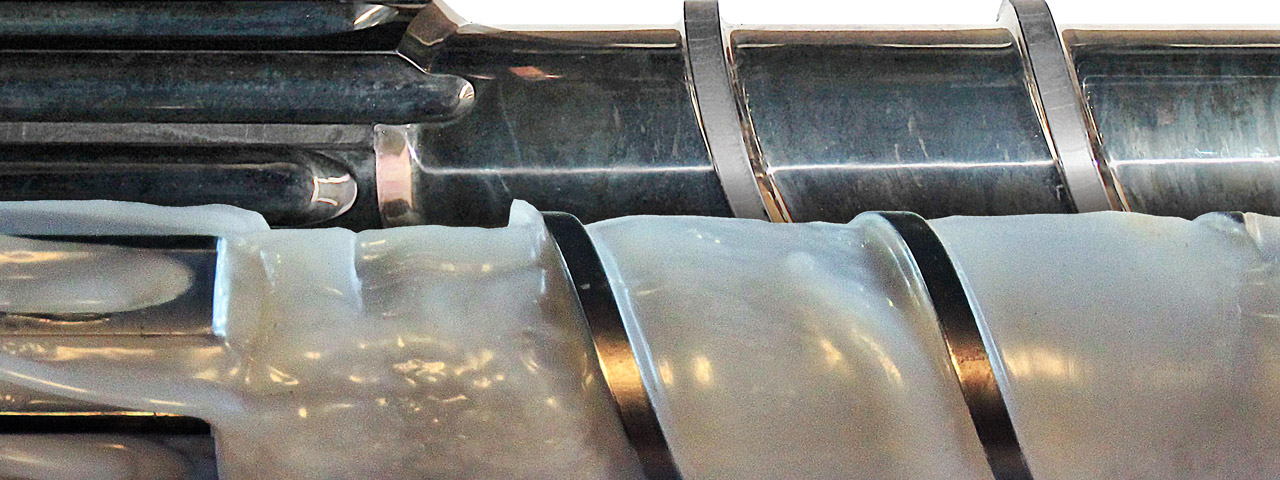

Clean extruder screws and screw tips, remove plastic

Screw cleaning

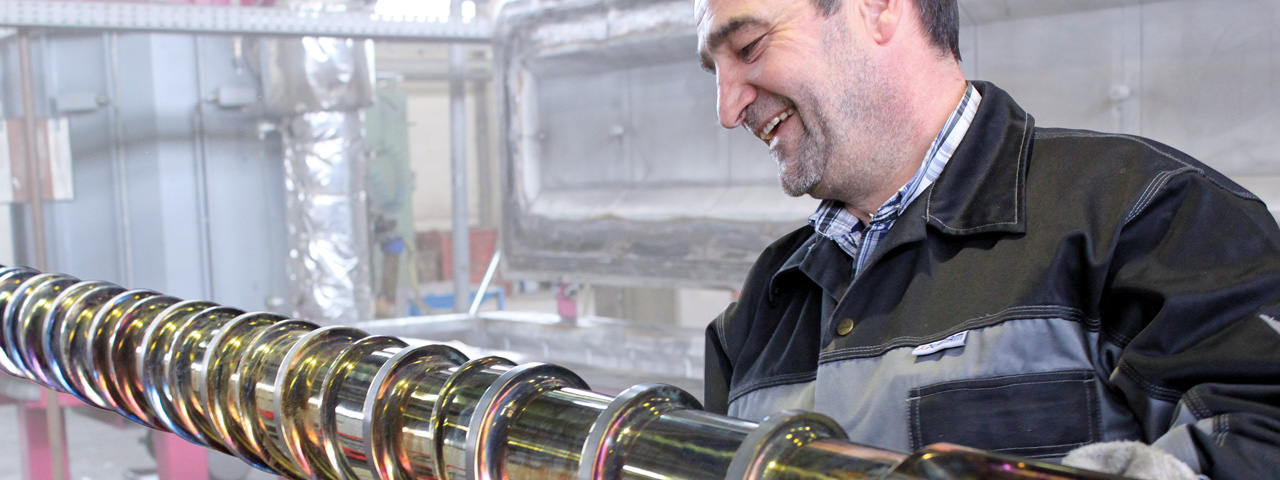

SCHWING removes all kinds of elastomer and plastic contamination on screws of all types in the shortest time possible. Whether meter long extruder screws (compounding screws), screw elements or smaller screw tips from the injection molding industry, specially adapted thermal cleaning processes, in conjunction with suitable post-processing guarantee the best results, without damaging the surfaces.

Manual cleaning processes still used in some industries using solvents, wire brushes, abrasive tools and blowtorches are not very suitable. They leave marks and damage on the surfaces like commonly used blasting processes. These unsuitable cleaning methods lead to premature contamination.

The service life of extrusion and injection molding screws are significantly increased with a professional thermal clean by SCHWING while reducing the maintenance costs.

Extruder screw cleaning

Deposits of degraded material build up on the screw by daily use during the processing of thermosets and thermoplastics and lead to loss of quality. These contaminants must be removed from the surfaces to ensure smooth and clean color or product changeover.

Rubber residue, adhesives, paint and organic contaminants can also be completely removed with the SCHWING technologies, leaving no residue.

Production costs can be significantly reduced with clean tools.

SCHWING supports extrusion businesses such as film and profile manufacturers with reliable and economical cleaning solutions, with which they can achieve a continually trouble-free production quality.

The systems from SCHWING clean also flat film dies, breaker plates with filters, and large components such as blown film heads, screen changers, breaker plates or extruder screws for plastics of all kinds, because they have special large and especially powerful machines available.

Cleaning injection molding machine parts

The careful and reproducible cleaning of screw tips, spinnerets, static mixers, etc. ensures longer service life of these key production tools.

Depending on the type of polymer and the structure of the component cleaning times can be as short as two to four hours. The removal of the adherent plastic takes place in only one process step and the cleaned parts can be quickly integrated into the production process again. Inorganic residues are removed using a suitable post-process (compressed air, glass bead blasting, etc.).